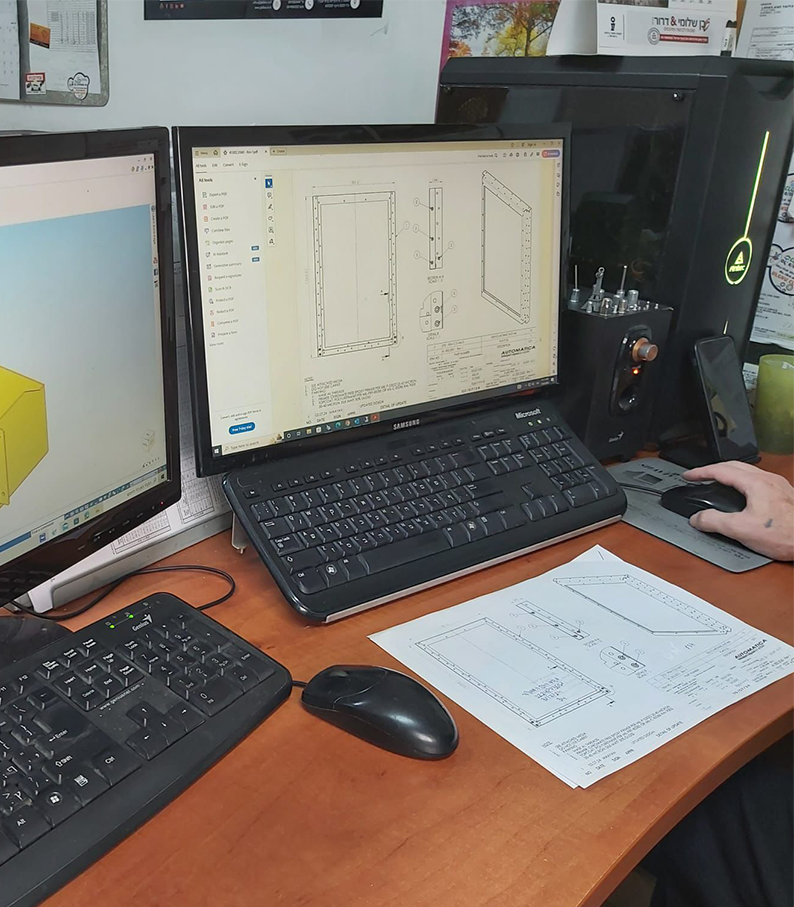

The production planning and control department, as its name implies, plans and supervises from the moment the order is received until the product is delivered to the customer. Every project that passes through the gates of Lahav & Yaffe Ltd. comes first to the PPC department, which accompanies it all the way. From planning purchase orders using an internal ERP system with a dedicated model, producing reports that assist in supervision and maintaining transparency with the customer, to the delivery of the product at the required time and quality. The department's employees are dedicated to their work, have experience and understanding in planning processes and synergy with operations.